Robotische Präzision trifft auf pharmazeutische Nachfrage

Herausforderung: Pharmazeutische Nachfrage mit Präzision und Sicherheit erfüllen

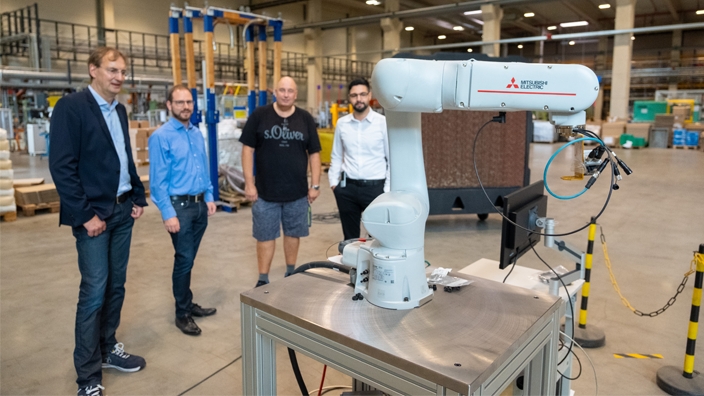

Lösung: Kompakte, innovative Robotik

Ergebnis: Hochgeschwindigkeitsproduktion ohne Beschädigungen

Warum dies wichtig ist

Our Stories

Sehen Sie sich das Video auf YouTube an

#Life Science#Industrieroboter - MELFA#Servomotoren#Mensch-Maschine- Interfaces (HMIs) - GOT

#Produktion#Industrieroboter - MELFA

PDF Herunterladen

DE#Food & Beverage#Machine Building#AC-Servosysteme MELSERVO#Mensch-Maschine- Interfaces (HMIs) - GOT#Industrieroboter - MELFA#Steuerungen

PDF Herunterladen

DE#Automotive#Material Handling#Steuerungen#Mensch-Maschine- Interfaces (HMIs) - GOT#Industrieroboter - MELFA