News

Note that the releases are accurate at the time of publication but may be subject to change without notice.

ROBOTIC SOLUTIONS FOR GROWING MARKETS AND SKILLS SHORTAGES

Ratingen, Germany – August 22, 2025

The global use of industrial robots remains high. According to the 2024 World Robotics Report published by the International Federation of Robotics (IFR), there are more than 4.28 million robots in use, which is a 10% increase from the previous year. In 2023, 541,000 new units were installed, marking the third consecutive year exceeding half a million. China remains the leader, accounting for 51% of all installations, followed by Japan, the United States, and South Korea. India and Brazil are also experiencing double-digit growth rates. These figures demonstrate that robot technologies are increasing production capacity and being successfully integrated into existing processes.

In 2023, 92,393 robots were installed in Europe (+9%), with Germany as the largest market with 28,355 units (+7%). The United Kingdom even recorded +51% with 3,830 units, driven by the automotive industry.

According to the IFR, 2024 saw the first signs of stabilization or a slight decline in installations, particularly in saturated markets. In Europe, for example, around 23,000 new robots were installed in the automotive industry, the second-best result in the last five years. In the long term, however, the IFR expects growth rates to rise again from 2026, driven by AI, new applications, and nearshoring.

AI and sustainability will shape 2025

The IFR sees significant momentum in 2025 from analytical, generative, and physical AI, humanoid robots, and sustainable robotics. New industries such as construction and laboratory automation are gaining in importance. At the same time, the shortage of skilled workers remains a key issue: According to a McKinsey Global Industrial Robotics Survey, 61% of companies cite a lack of automation experience as an obstacle, while 30% complain of difficulties in recruiting qualified employees.

No-code approaches to combat the shortage of skilled workers

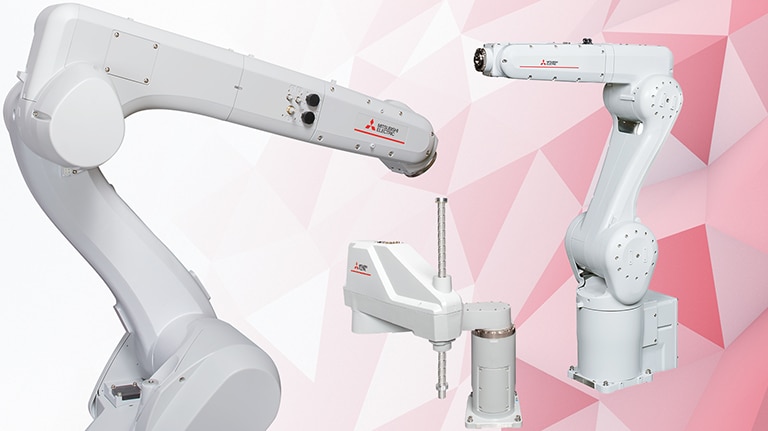

This is where Mitsubishi Electric comes in with its MELFA RV-CR (articulated arm robot) and RH-CRH (SCARA) series, offering compact, cost-efficient solutions that are particularly easy to use. The CR800 controller enables visual programming via function blocks, allowing even employees with no prior knowledge of robotics to implement applications. The MELSOFT RT ToolBox3 software allows simulations to be carried out in advance, reducing programming effort and minimizing errors.

"The demand is there, both in large and small production facilities," explains Michael Finke, Product Manager Robots at Mitsubishi Electric. "The MELFA RV-CR and RH-CRH series were specifically developed as cost-effective and compact solutions for a wide range of applications."

Easy integration and low maintenance

According to the SYSPRO study, 30% of manufacturers have problems integrating new technologies. The two robot series are therefore optimized for quick integration into existing production lines: compact design, integrated cabling and pneumatic lines, and battery-free servo motors reduce maintenance requirements. The new R86TB teaching box with a 10.1" display and 3D visualization makes setup, diagnostics, and programming easier with —compatible with current and previous MELFA robots.

Wide range of applications and user-friendliness

Typical applications range from picking, packaging, and sorting to quality control and assembly in the automotive industry, laboratories, mechanical engineering, and other industries. Thanks to support for the e‑F@ctory concept and compatibility with CC‑Link IE TSN, the robots can be seamlessly integrated into industrial networks.

Two series for different needs

Mitsubishi Electric has introduced two robot series for manufacturing environments.

- MELFA RV-CR series: Vertical articulated arm robots with a compact design and low maintenance requirements, ideal for industrial applications.

- MELFA RH-CRH series: SCARA robots with 65% lower height and 50% less weight than the previous FR series – optimized for small footprints, fast cycle times, and standard network connectivity

Perfect industrial compatibility

Combining user-friendliness, energy efficiency, and flexible integration, the MELFA RV-CR and RH-CRH series offer a real answer to the shortage of skilled workers and increasing automation requirements—even in new industries outside of traditional manufacturing.

For more information on the MELFA RV-CR and RH-CRH series robots, please visit:

[Sources]:

The images distributed with this press release are for editorial purposes only and are subject to copyright. The images may only be used to accompany the press release mentioned here; any other use is prohibited.

Image

Image 1: SCARA and articulated arm robots from Mitsubishi Electric's CR series

[Source: Mitsubishi Electric Europe]

About Mitsubishi Electric Corporation

With more than 100 years of experience in providing reliable and high-quality products, Mitsubishi Electric is a globally recognized leader in the manufacture, marketing, and sale of electrical and electronic equipment for information processing and communications, space development and satellite communications, consumer electronics, industrial technology, energy, mobility and building technology, and heating, cooling, and air conditioning technology. Based on its motto "Changes for the Better," Mitsubishi Electric strives to enrich society with technology. At the end of the fiscal year on March 31, 2025, the company achieved consolidated sales of US$36.8 billion*. It has sales offices, research companies, development centers, and manufacturing facilities in over 30 countries. Mitsubishi Electric has been represented in Germany since 1978 as a subsidiary of Mitsubishi Electric Europe. Mitsubishi Electric Europe is a wholly owned subsidiary of Mitsubishi Electric Corporation in Tokyo.

Further information is available at www.MitsubishiElectric.com

- Amounts in US dollars are converted from yen at the rate of ¥150 = US$1, the approximate rate on the Tokyo foreign exchange market on March 31, 2025.

About the Mitsubishi Electric Factory Automation Business Group

Mitsubishi Electric offers a wide range of automation and processing technologies, including controllers, drive products, power distribution and control products, spark erosion machines, electron beam machines, laser processing machines, numerical computer controls, and industrial robots, thereby contributing to higher productivity and quality in manufacturing ( ). In addition, extensive service networks around the globe provide direct communication and comprehensive support for customers. The global slogan "Automating the World" illustrates the company's approach of using automation for the benefit of society through the use of advanced technologies, the transfer of know-how, and support for customers as a trusted partner.

For more information about the history of "Automating the World," please visit:

Mitsubishi Electric Industrial Automation

Mitsubishi Electric Europe B.V., Industrial Automation, is headquartered in Ratingen near Düsseldorf. It is part of Mitsubishi Electric Europe B.V., which has been represented in Germany since 1978 and is a wholly owned subsidiary of Mitsubishi Electric Corporation, Japan. Its task is to manage sales, service, and support for the Industrial Automation division throughout the DACH region and Benelux.

Further information can be found at