News Releases

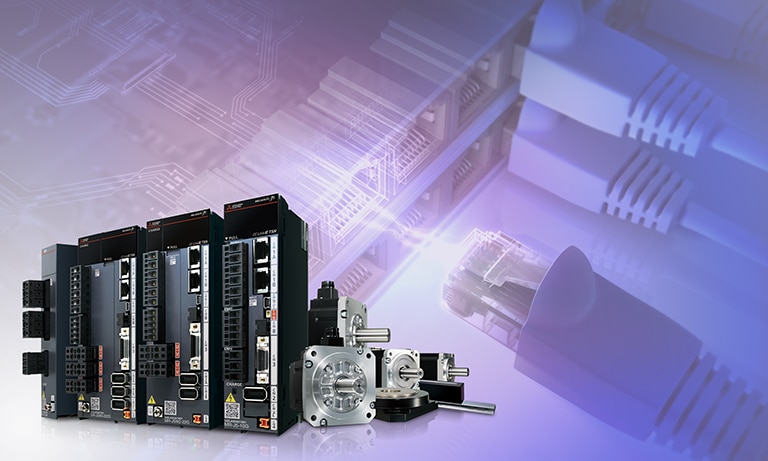

INDEPENDENT AND FLEXIBLE – A TOAST TO OPEN CONNECTIONSHow servo systems can benefit from OPC UA, EtherCAT and CC-Link-IE-TSN.

Ratingen, 5.2.2025

In the age of digitalization, the networking of machines, systems and plants is a decisive success factor. Open network connections play a central role in enabling cross-manufacturer integration and flexible production environments. Servo systems are a prime example of the benefits of such technologies, particularly with OPC-UA, OPC-UA FX, EtherCAT and CC-Link-IE-TSN.

The benefits of open and standardized network connections, that can be used across industries and markets, are obvious. In general, they enable the horizontal and vertical integration of a wide variety of machines, systems and peripherals. This creates consistent data availability at all levels, from the sensor to the cloud, and facilitates data-driven optimization in production.

Standardized fieldbus protocols and profiles make it much easier to commission servo systems at the field level. Fieldbus profiles such as CiA 402 are currently in use, and OPC UA FX will also play an important role in the future. The direct integration of these communication protocols into the servo controller eliminates the need for additional gateways. This results in cost savings, simplified commissioning and reduced maintenance requirements. At the same time, this standardization enables machine builders to change manufacturers with minimal effort and efficiently transfer their existing know-how.

Intelligent and forward-looking drive technology

Networking enables deep integration of servo drives into digital value chains. Connection to intelligent production ecosystems also makes it possible to integrate AI-based technologies, cloud computing and digital twins into operations. This leads to greater transparency and more comprehensive control of the entire value chain. Servo systems play a key role here, as they not only enable precise and dynamic motion control, but can also act as data collectors and communication nodes.

Author: Eric Irabor, Junior Product Manager Servo Systems Mitsubishi Electric

Image captions:

Image 1: Servo systems from Mitsubishi Electric are open to all networks.

[Source: Mitsubishi Electric]

The image(s) distributed with this press release is/are intended for editorial use only and is/are subject to copyright. The image(s) may only be used for the press release mentioned here, no other use is permitted.

About Mitsubishi Electric Corporation

Mitsubishi Electric Corporation (TOKYO: 6503) has more than 100 years of experience in manufacturing reliable, high-quality products and is a recognized world leader in the manufacturing, marketing and sales of electrical and electronic equipment used in information processing and communications, space development and satellite communications, consumer electronics, industrial technology, energy, transportation and building equipment. Mitsubishi Electric enriches society with technology in the spirit of its "Changes for the Better". The company recorded sales of 5,257.9 billion yen (34.8 billion US dollars*) in the fiscal year ending March 31, 2024.

Further information can be found at www.MitsubishiElectric.com.

- *Amounts in US dollars are converted from yen at the rate of ¥151=US$1, the approximate rate on the Tokyo foreign exchange market on March 31, 2024.

About the Mitsubishi Electric Factory Automation Business Group

Mitsubishi Electric offers a wide range of automation and processing technologies, including controls, drive products, power distribution and control products, electrical discharge machines, electron beam machines, laser processing machines, computer numerical controls and industrial robots, contributing to higher productivity - and quality - in manufacturing. In addition, the extensive service networks around the globe provide direct communication and comprehensive support for customers. The global slogan "Automating the World" illustrates the company's approach of using automation for the benefit of society by using advanced technologies, sharing know-how and supporting customers as a trusted partner.

You can find more information about the history of "Automating the World" here:

www.MitsubishiElectric.com/fa/about-us/automating-the-world

Factory Automation EMEA

Mitsubishi Electric Europe B.V., Factory Automation EMEA has its European headquarters in Ratingen near Düsseldorf, Germany. It is part of Mitsubishi Electric Europe B.V., a wholly owned subsidiary of Mitsubishi Electric Corporation, Japan, which has been present in Germany since 1978. The task of Factory Automation EMEA is to manage sales, service and support via the network of local subsidiaries and distributors throughout the EMEA region.

Further information can be found at emea.mitsubishielectric.com/fa

Note

Note that the press releases are accurate at the time of publication but may be subject to change without notice.