Drive down cost

Mitsubishi Electric has both the software and hardware solutions to eliminate complexity from every stage of a build, from design and development through to commissioning and maintenance.

Printing success

Software solutions lineup

Product lineup

We’re here to help you to maximise the potential of your machine.

Technical assistance and business support

Reducing production and build times

Optimising machine design and performance

Whitepaper - Intelligent Control Systems

Whitepaper Download Form

Download Whitepapers

Machine building strategies and solutions

Contact us for more information

Competencies

Our Stories

![HAMBI Steel Mesh [Img 1]](https://eu-images.contentstack.com/v3/assets/blt5412ff9af9aef77f/blt9d766b0fc1b7a486/67bf27a084fd866c89de3c96/Hambi_maschinenbau.jpg?auto=webp&quality=100&format=jpg&disable=upscale)

2025-01-09

The world's first fully automated line for reinforcing steel mesh

Hambi Terhoeven GmbH & Co KG

Watch the video on YouTube

#Machine Building#Material Handling#Visualization#Programmable Controllers MELSEC#Servo motors

![[Thumbnail] Innovation in dairy production](https://eu-images.contentstack.com/v3/assets/blt5412ff9af9aef77f/bltfae4cdd88be35f7a/675823ae19771e6809a85679/Innovation_in_dairy_production.png?auto=webp&quality=100&format=jpg&disable=upscale)

Watch the video on YouTube

#Machine Building#Food & Beverage

Watch the video on YouTube

#Food & Beverage#Machine Building#Sustainability#Energy#Visualization#Inverters-FREQROL#Controllers

2024-04-19

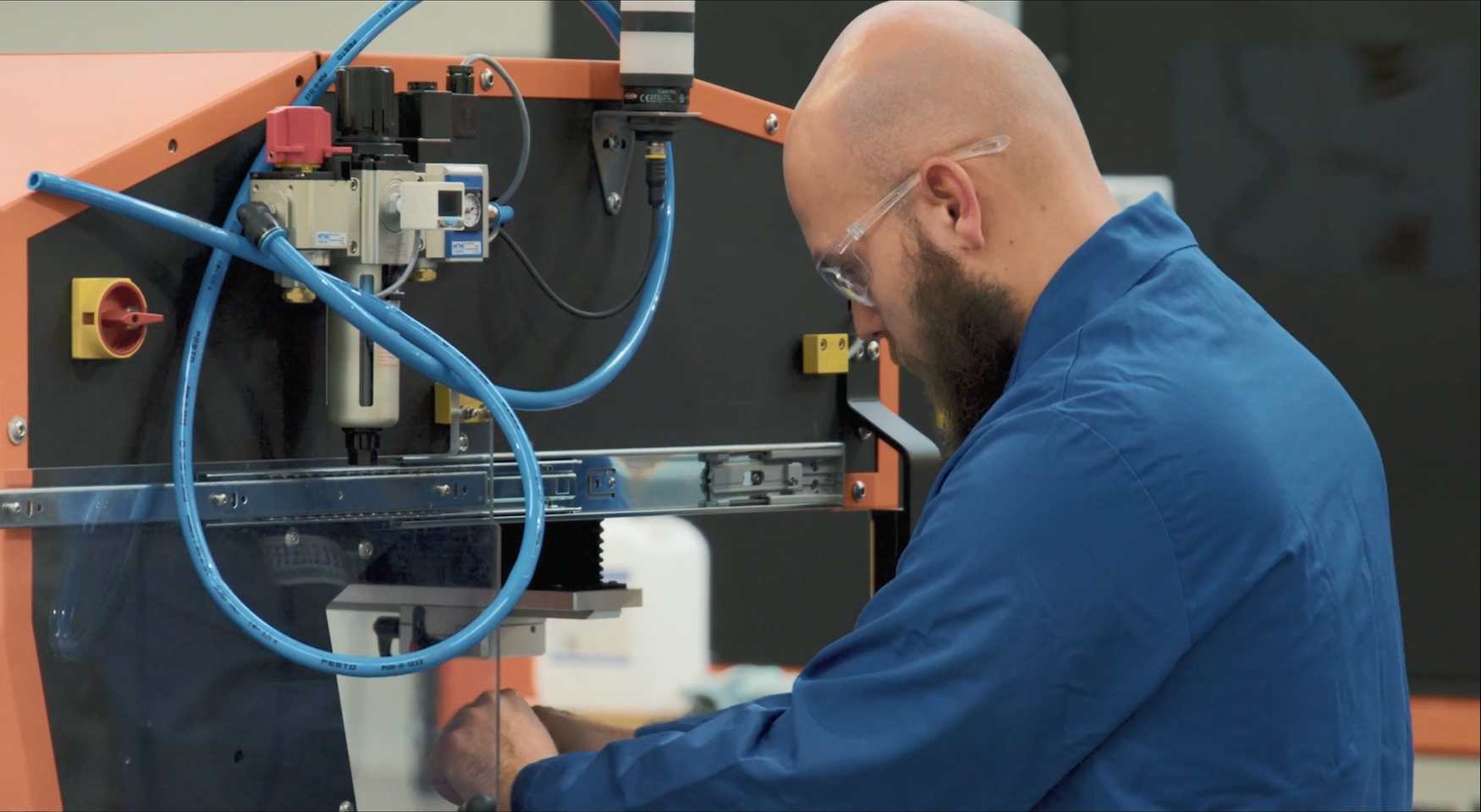

Industrial Printing Solutions

KELLER

Watch the video on YouTube

#Machine Building#Life Science

.jpg?auto=webp&quality=100&format=jpg&disable=upscale)

#Machine Building#AC Servos-MELSERVO

![[Thumbnail] Quality Control in High Speed Inhaler Testing](https://eu-images.contentstack.com/v3/assets/blt5412ff9af9aef77f/bltec0b49d0ea7e4e73/673211f255ee8a3647f032bc/QualityControl_inhaler.jpg?auto=webp&quality=100&format=jpg&disable=upscale)

Watch the video on YouTube

#Life Science#Machine Building#Controllers#Robots

Download PDF

DE#Food & Beverage#Machine Building#AC Servos-MELSERVO#Human-Machine Interfaces (HMIs) - GOT#Industrial Robots - MELFA#Controllers

Download PDF

DE#Life Science#Packaging#Machine Building#Controllers#Human-Machine Interfaces (HMIs) - GOT